Services

Fresh Arrival

UPVC Interiors in Hosur: SPC Interiors

UPVC Interiors in hosur: SPC Interiors, also known as Jomson SPC Interiors, is a company specializing in interior design and modular kitchen solutions, particularly using SPC (Stone Polymer Composite) materials. They offer a range of services including modular kitchen design, wardrobe design, and other interior work. SPC Interiors caters to various spaces like residential apartments, offices, and commercial complexes.

PVC & WPC bathroom Doors

Cozy Corner Interiors is selling high quality bathroom doors in hosur and surrounding areas. WPC 24mm to 30mm doors PVC 24, 30mm, Heavy embossed and super heavy doors.

Home Construction

Cozy Corner Interior is tied with some leading construction companies and extent our wings is construction filed also.

Interior Design

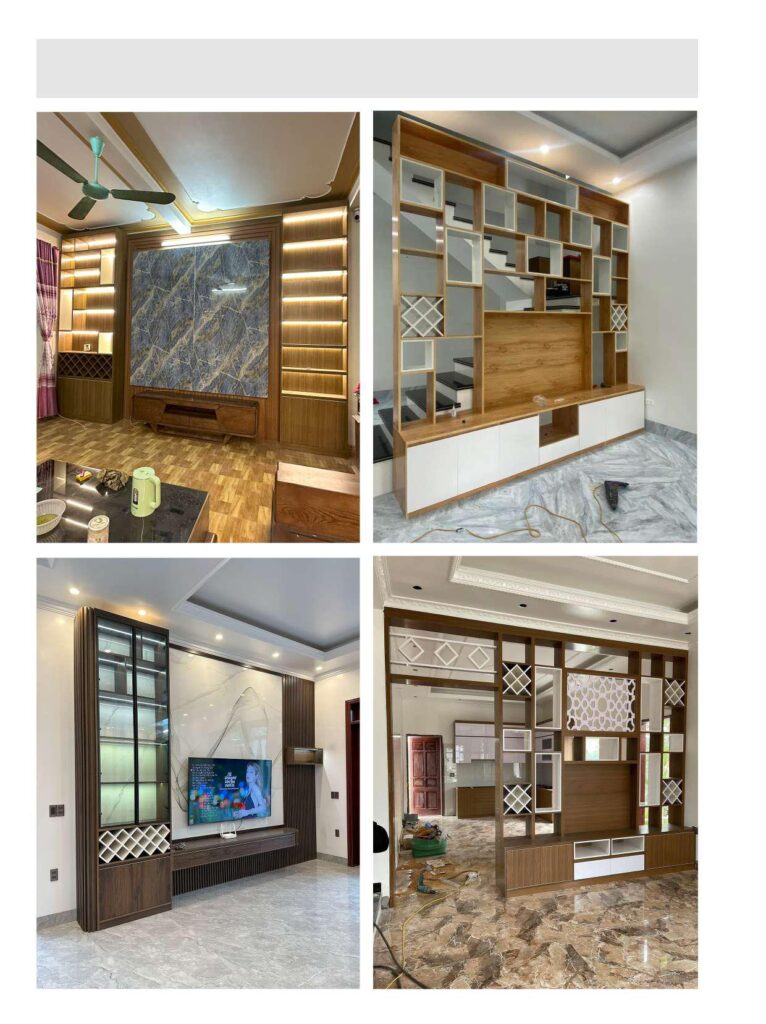

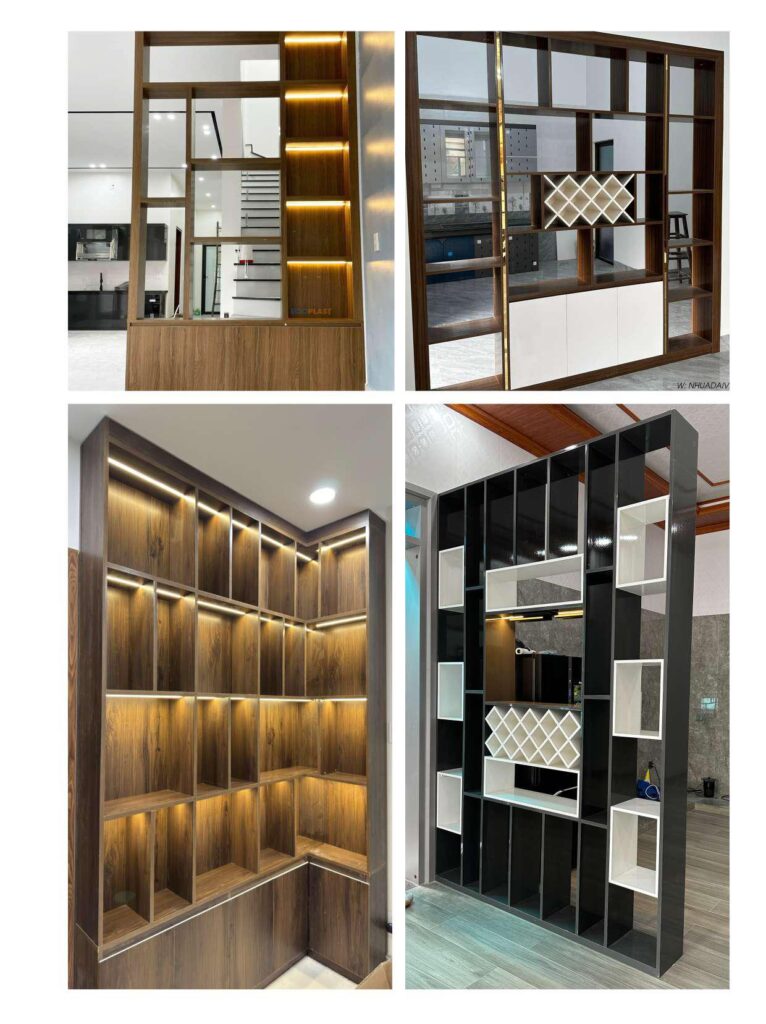

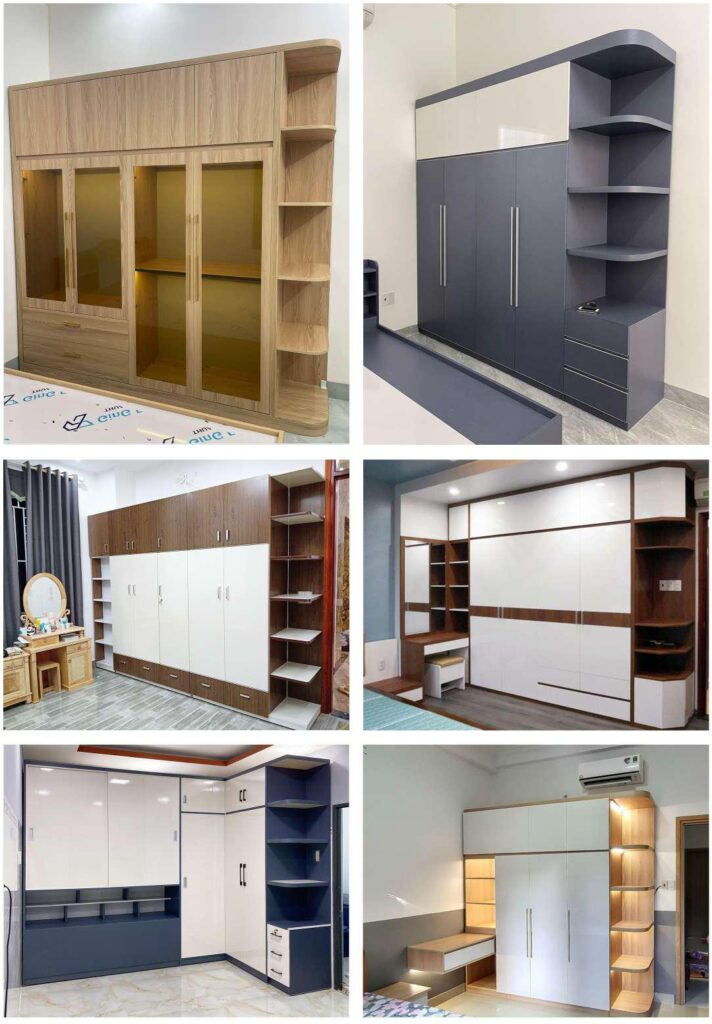

We are mainly dealing with interior design work like PVC, UPVC and SPC modular kitchen, Wardrobe design, TV Showcase, Pooja Room design, Loft covering and more.

Furniture

Cozy Corner interior is directly sellng some products like Bedroom cots, Mamdir Unit, Shoe racks and Book selfs.

SPC and UPVC cataloges download here

UPVC, which stands for unplasticized polyvinyl chloride, is a rigid and durable material that has become a popular choice for various interior applications beyond its traditional use in windows and doors. Its unplasticized nature makes it stronger and more resistant to wear and tear than regular PVC.

Key Applications of UPVC in Interiors

Modular Kitchens: UPVC is a top contender for modular kitchen cabinets and shutters. It’s highly resistant to moisture, termites, and fire, making it an excellent material for a kitchen environment. Its smooth surface is also easy to clean and maintain. UPVC kitchens come in various designs, from sleek, minimalist to more elaborate styles.

Wardrobes and Cupboards: UPVC is a durable and low-maintenance option for wardrobes and storage units. It’s resistant to moisture and termites, which can be a significant advantage over traditional wood or plywood, especially in humid climates.

Windows and Doors: This is the most common application of UPVC. It is used for window frames, sills, and doors, offering excellent thermal and sound insulation. UPVC windows and doors are known for their durability, weather resistance, and low maintenance. They come in various styles, including casement, sliding, and French windows, and can be customized with different colors and finishes, including wood grain.

Wall Paneling and Ceilings: UPVC panels can be used to create accent walls or modern ceiling designs. They are waterproof, easy to install, and can add a sleek, clean look to a room.

Bathroom Furniture: Due to its exceptional water resistance, UPVC is an ideal material for bathroom vanities, cabinets, and shower enclosures.

Benefits of UPVC Interiors

Durability and Longevity: UPVC is a tough and resilient material that can withstand daily use without rotting, rusting, or corroding. It is also resistant to UV rays, which prevents it from fading over time.

Low Maintenance: Unlike wood, UPVC does not require regular sanding, varnishing, or painting. It is easy to clean with a simple wipe-down, saving you time and money on upkeep.

Moisture and Termite Resistance: This is one of the most significant advantages of UPVC, especially for areas like kitchens and bathrooms. It is not susceptible to water damage or termite infestations.

Energy Efficiency: As a poor conductor of heat, UPVC helps in thermal insulation. This can lead to reduced reliance on heating and cooling systems, potentially lowering your energy bills.

Sound Insulation: When used for windows and doors, UPVC can significantly reduce external noise, creating a quieter indoor environment.

Fire Resistance: UPVC is a fire-retardant material and does not support combustion, adding an extra layer of safety to your home.

Eco-Friendly: UPVC is a recyclable material, making it a sustainable choice for homeowners.

Design Flexibility: UPVC products are available in a wide range of colors, finishes, and designs, allowing them to complement various interior design styles, from modern and minimalist to more traditional looks.

While UPVC offers numerous benefits, it’s important to choose high-quality products and professional installation to ensure longevity and performance.

Quality

The quality of unplasticized polyvinyl chloride (uPVC) products can be determined by examining several key factors related to their material composition, fabrication, and performance. High-quality uPVC is a durable, low-maintenance, and energy-efficient material used in various applications, particularly for windows and doors. Key Indicators of Quality Material Composition: Quality uPVC profiles should be made from lead-free materials to ensure they're non-toxic and safe, especially for products like pipes for drinking water. They should contain high-grade fillers and chemicals that enhance their strength and durability. For products exposed to sunlight, like windows and roofing sheets, the presence of UV stabilizers (such as titanium dioxide) is crucial to prevent the material from becoming brittle or discolored over time. Fabrication and Build: A well-fabricated uPVC product will have a multi-chambered design, which provides better thermal and acoustic insulation. The walls of the profile should have a certain thickness, typically between 2.2 mm and 3 mm, for stability. Look for clean, properly sealed joints and galvanized steel reinforcements within the profile chambers, which add significant strength and prevent warping. Hardware and Installation: The quality of the hardware, including handles, locks, hinges, and rollers, is vital for long-term functionality and security. These components should be made of corrosion-resistant materials. Correct installation is just as important as the product's quality. This includes proper frame fixing, appropriate use of fasteners, and the application of tight rubber gaskets and silicone sealants to ensure the product is airtight and watertight. Certifications and Standards: To verify quality, look for products that meet international and national standards. For example, in India, certifications from the Bureau of Indian Standards (BIS) like IS 4985 and IS 15778 are important for pipes. Internationally, certifications like ISO, RAL, and BSI guarantee that the products have undergone rigorous testing for various properties, including strength, weatherability, and chemical composition. This video highlights some of the key things to look for when checking the quality of uPVC windows, such as the welding, hardware, and drainage slots. Top secrets to check Quality of uPVC windows! Doors

Modern

Modern UPVC has moved beyond the simple white frames it was once known for. Today, it's a versatile material that offers a wide range of aesthetic options, allowing it to seamlessly integrate into various architectural styles. Design Flexibility: Modern UPVC comes in a variety of colors and finishes, including wood-grain textures and sleek matte finishes like black and grey. This allows for extensive customization to match a building's design. Minimalist Aesthetics: Current design trends favor clean lines and large glass surfaces. UPVC can be manufactured into slim, sleek frames that maximize the glass area, enhancing natural light and creating a modern, uncluttered look. Open-Concept Living: UPVC is used to create large, expansive openings like sliding, bi-fold, and French doors. These allow for a seamless transition between indoor and outdoor spaces, a key feature of modern architecture. Smart Home Integration: UPVC windows and doors can be integrated with modern smart home technology, such as automated locking systems, motion sensors, and programmable ventilation. Beyond doors and windows, modern UPVC is used in various other applications, including: Plumbing: For durable and corrosion-resistant pipes and fittings. Roofing and Cladding: For lightweight, protective, and aesthetic roofing sheets and facades. Interiors: As a termite-proof and moisture-resistant alternative to wood for kitchen cabinets, wardrobes, and false ceilings.

Budget friendly interiors is available with us in minimum 1 third of Wooden cost

Cozy Corner is extent of winks to the middle class people who are wants to do interior within they are budget.

Budget friendly interiors includes PVC glossy materials like Mirror Profiles, Polywood, Sarvesh light materials

Why uPVC is Budget-Friendly

Lower Material Cost: uPVC is generally more affordable than materials like wood, aluminum, and steel. The manufacturing process of this synthetic polymer is less expensive, which translates to a lower price per square foot.

Reduced Installation Costs: The material is lightweight and easy to work with, which can lead to lower labor costs and faster project completion.

Low Maintenance: Unlike wood, uPVC doesn’t require regular painting, sealing, or polishing. It is resistant to rot, rust, and termites, which saves money on maintenance and repair in the long run.

Energy Efficiency: uPVC is an excellent insulator, helping to reduce heat transfer. This can lead to savings on energy bills for heating and cooling, making it a smart long-term investment.

Common uPVC Interior Applications

While most commonly associated with doors and windows, uPVC is a versatile material used for a wide range of interior applications:

Modular Kitchens & Cabinets: uPVC is a popular choice for kitchen cabinets due to its resistance to water and termites. It’s easy to clean and can be customized with various colors and finishes to mimic the look of wood.

Wardrobes & Cupboards: Its durability and low-maintenance nature make it ideal for wardrobes and storage units in bedrooms and other areas.

Wall Paneling & False Ceilings: uPVC panels can be used to create decorative and functional wall cladding or false ceilings, offering a clean, modern look.

TV Units & Showcases: uPVC is used to construct stylish and sturdy TV units and other display furniture.

Doors and Windows: This is the most common use of uPVC. It provides excellent insulation and soundproofing, and is a more durable and practical alternative to timber.

Design Ideas for Budget-Friendly uPVC Interiors

Faux Wood Finishes: For a classic and elegant look without the high cost of real wood, consider uPVC with a wood-grain finish. This gives you the aesthetic of wood with the practicality and low maintenance of uPVC.

Minimalist & Modern Styles: The clean lines and sleek finishes of uPVC make it a perfect fit for minimalist and contemporary design themes.

Customization: uPVC is highly customizable. You can get it in a variety of colors, styles, and designs to match your home’s aesthetic.

Utilize for Functional Areas: Focus on using uPVC in areas that require high durability and low maintenance, such as bathrooms and kitchens. This is where it provides the most value for money.

Recent Projects

PVC Wall paneling

PVC (polyvinyl chloride) wall paneling is a modern interior decoration material that serves as an alternative to traditional wall finishes like paint, wallpaper, or tiles. Made from PVC resin, these panels are lightweight, durable, and available in a wide variety of designs.

Key Features and Benefits

Water and Moisture Resistance: PVC is naturally waterproof, making these panels an excellent choice for moisture-prone areas like bathrooms, kitchens, and basements. They won’t warp, swell, or support the growth of mold and mildew.

Durability and Low Maintenance: PVC panels are resistant to stains, scratches, and fading. They are easy to clean with a damp cloth and mild soap, and they don’t require frequent painting or repair. With proper care, they can last for many years.

Cost-Effectiveness: PVC wall panels are generally more affordable than many other wall finishing options, such as tiles or solid wood, making them a budget-friendly solution for renovations.

Easy and Quick Installation: The panels are lightweight and often feature a tongue-and-groove or interlocking system, which simplifies the installation process. They can be installed directly over existing surfaces like old tiles, drywall, or brick, often making it a DIY-friendly project.

Versatility in Design: PVC panels are available in a vast range of colors, patterns, and textures. You can find options that mimic the look of natural materials like wood, marble, or brick, as well as 3D-textured panels, solid colors, and glossy or matte finishes.

Types of PVC Wall Panels

PVC wall panels come in various forms, including:

PVC Sheets: These are flat panels, often used to create a seamless look or to mimic the appearance of other materials with printed designs.

3D PVC Wall Panels: These panels have an embossed or raised pattern, adding depth and visual interest to a wall.

Fluted PVC Panels: Characterized by a series of straight, grooved recesses, these panels add texture and can help with sound absorption.

Laminated PVC Panels: These panels have a laminated layer on the surface, providing a high-gloss or specific-texture finish.

PVC Foam Boards: These are thicker and more rigid than standard PVC sheets and are often used for external wall cladding due to their durability and insulation properties.

Potential Drawbacks

While PVC wall paneling offers many advantages, it’s important to consider some potential drawbacks:

Aesthetic: Lower-quality PVC panels can sometimes have a “plastic” or artificial appearance. Choosing panels with a matte or textured finish can help avoid this.

Heat Sensitivity: PVC can warp or deform when exposed to extreme heat. It is not recommended to install them near heat sources like fireplaces or behind a stove unless they are specifically designed to be heat-resistant.

Environmental Concerns: PVC is a synthetic material and is not biodegradable. The manufacturing process can also have environmental impacts. Some brands, however, offer panels with recycled content or use more environmentally friendly production methods.

Fragility: While durable against daily wear and tear, PVC panels can be susceptible to damage from sharp or heavy objects.

Installation Process

The installation of PVC wall panels is typically a straightforward process. The basic steps often involve:

Preparation: Ensure the wall surface is clean, dry, and smooth.

Measurement and Cutting: Measure the wall and cut the panels to the required size using a fine-toothed saw or a utility knife.

Application: Apply a strong, solvent-free adhesive to the back of the panel in a zigzag pattern or a grid.

Placement: Align the panel and press it firmly onto the wall. For interlocking panels, secure the tongue-and-groove system. Screws or nails can also be used for added security.

Finishing: Use corner trims, edge profiles, and a silicone sealant to create a clean, finished look and to protect against moisture, especially in wet areas.

PVC False ceiling

A PVC false ceiling is a type of ceiling made from polyvinyl chloride (PVC) panels. It is a cost-effective, lightweight, and durable alternative to traditional false ceiling materials like gypsum or plaster of Paris (POP). PVC panels are factory-manufactured and come in various designs, colors, and sizes, with a hollow core and a smooth, often shiny, surface.

Advantages of a PVC False Ceiling

Water and Moisture Resistant: PVC is a plastic material that does not absorb water, making it an excellent choice for moisture-prone areas like bathrooms, kitchens, and balconies. It prevents the growth of mold and mildew.

Durable and Lightweight: PVC panels are strong and durable, and they don’t warp or bend over time. Their lightweight nature makes them easy to transport and install, reducing the stress on the building’s structure.

Easy to Install: The installation process is generally quick and clean, as it does not involve a lot of dust or debris. The panels often use a tongue-and-groove or interlocking system, which simplifies the process.

Low Maintenance: PVC ceilings are very easy to clean and do not require painting, varnishing, or special coatings. A simple wipe with a damp cloth is usually sufficient to keep them looking new.

Cost-Effective: PVC is generally more affordable than other false ceiling materials like gypsum or wood, making it a budget-friendly option.

Termite and Pest Resistant: Unlike wood, PVC is impervious to termites and other insects, which extends its lifespan.

Disadvantages of a PVC False Ceiling

Synthetic Appearance: While PVC panels can mimic the look of other materials like wood or marble, they may still have a “plastic” or artificial appearance. The joints between panels can also be visible.

Limited Heat Resistance: PVC is a type of plastic and can be damaged when exposed to high temperatures. It is recommended to use energy-efficient LED lights and avoid heat-emitting bulbs with PVC false ceilings. This also makes them unsuitable for areas like a kitchen stove.

Flammability and Toxic Fumes: PVC is a synthetic material that can be flammable. When burned, it can release toxic fumes, including dioxins, which pose a serious health risk.

Environmental Concerns: As a plastic material, PVC is not easily biodegradable, and its production and disposal raise environmental concerns.

Installation Process

While it is possible to install a PVC false ceiling as a DIY project, it’s often recommended to hire a professional for the best results. The general process involves:

Measurement and Planning: Accurately measure the room’s area to determine the number of panels needed. Plan the layout, taking into account any existing fixtures like lights or vents.

Preparation: Ensure the ceiling surface is clean, smooth, and free of imperfections.

Frame Installation: Install a grid-like framework on the existing ceiling.

Panel Installation: Cut the PVC panels to size and attach them to the framework using screws, staples, or a clip system. The panels are typically interlocked for a seamless appearance.

Finishing: Install trim or edge tiles around the perimeter to hide any cut edges and provide a polished, professional look.